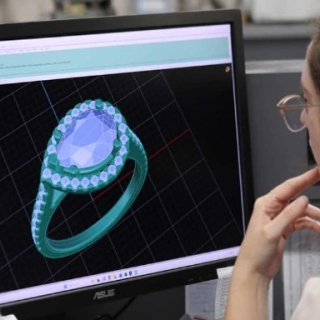

R&D & CAD Designers

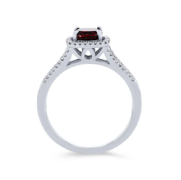

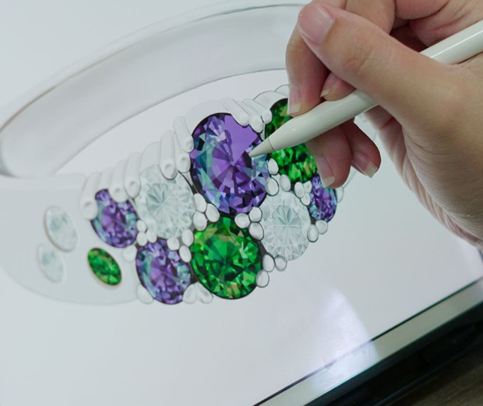

As a leading jewelry manufacturer that mainly works with customization orders, we provide all the tools to assist you bring your designs and collection ideas into life. Whether you are a jewelry designer, brands, global retailers, or a beginner designer with a jewelry idea, we are here to assist and develop from sketch to finished item.

As a part of our R&D department, we have In-House CAD designers, specialist designers to support and provide you with CAD/CAM services, which allow jewelry designers and retailers to bring any custom jewelry idea into reality. Our clients no longer have the limitation of what they can physically create by hand. Instead, a computer software program can help turn a creative and innovative design concept into reality.

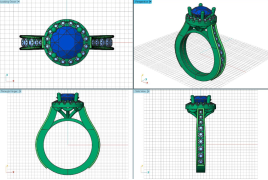

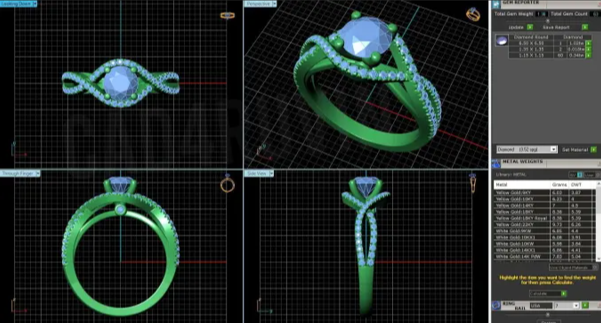

N.E.F provides our clients with the ability to view the piece of jewelry from all types of angles, including the inside, from the top, or the sides with the intention to demonstrate how the final design is going to be looks like. As we do not limit our clients with any minimum orders for custom designs, The CAD/CAM services at N.E.F are ideal to create just a single unique piece for one of your clients, or a few additional new designs to your private collection. Contact Us

CAD & CAM Services

CAD and CAM services are often considered to be the same service, nevertheless, they are two different types of services that are very helpful to jewelry retailers and designers.

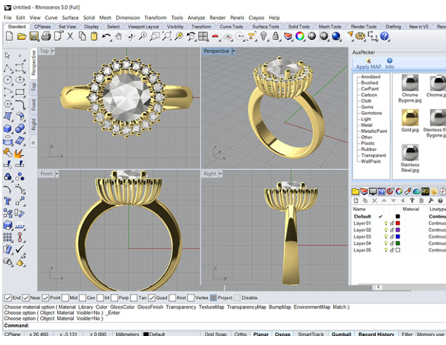

CAD (computer-aided design) describes the use of computer software programs to create 2D or 3D models. When the design phase using the CAD software is complete, we deliver a screenshot from the .STL or .3DM file(s) along with digital renders to illustrate the entire design and layout of the jewelry piece for final approval. That file is then used to create physical prototypes of the jewelry, which are made with the use of CAM software and growing machines.

CAM (computer-aided modeling) is the use of software programs and machinery to create and manufacture a 3D object. Upon completion of working with a CAM program and machines, a 3D wax model is created which physically represents the way the final product will look.

CAD and CAM services are often combined because they are so similar. Typically, the CAD software is used to create a digital layout of a piece of jewelry, whereas the CAM software/growing machines generate a prototype of the final product.

CAD (computer-aided design)

CAM (computer-aided modeling)

DEVELOPMENT IN HOUSE POLICY

Custom design development requires from the client to submit a $100 mold deposit per each design. The deposit can be refunded to the customer if the total amount of the order is reached $1,500 (can be mixed with other models).

Minimum deposit is necessary in all cases of product development to insure seriousness and commitment of the client. Once the design is developed, we allow the customer to make one modification at no additional cost.

A sample shipping fee ($20-25) will be charged for sending the sample for approval before starting the mass production stage.

RECEIVING A CAD FILE FROM THE CLIENT

In a case that the customer can provide the CAD file and prefers us to use it for direct printing, our designer will inspect the CAD file to make certain it can be used before send to 3D printing. If any modifications are necessary, the designer will inform the customer.

Once the model is printed, the CAD designer will provide to client WAX model pictures from several angles for review and approval before sending the model to cast metal.

Fast and Trustworthy service

At N.E.F we certainly comprehend that as soon as your wishing design or special client request comes, you are expecting to have these done fast as possible. No one wants to wait weeks for a prototype of the finished product. That is why N.E.F offers a 48 hours service on all our standard CAD designs.

A 48 hours service means that from the time your personal designer have received all the necessary design details from you, a finished CAD will be ready to send to you within 48 hours.

Even though our CAD jewelry design services are quick, they are extremely reliable. Our production methods are designed to produce the highest quality output. Next stage will be to receive a final confirmation from the client end and the Wax model will be printed in one of our 3D printers. Within 4-7 days the finished item is ready to be shipped. Contact Us

Ready to commence or further assistance is needed?

Leave us a message and we guarantee to provide you with a prompt response within the same day.