N.E.F PROFESSIONAL GOLD & SILVER JEWELRY CASTING SERVICES

In this page we’ll briefly sharing the unique casting process we use at N.E.F for solid Gold and 925 Silver jewelry. Every step of the casting process is closely monitored to ensure the highest level of quality.

At our factory we use nothing less than the excellent quality available for casting machinery and casting equipment’s, which mainly use for custom designs Jewelry and our private label collection.

CASTING STAGES

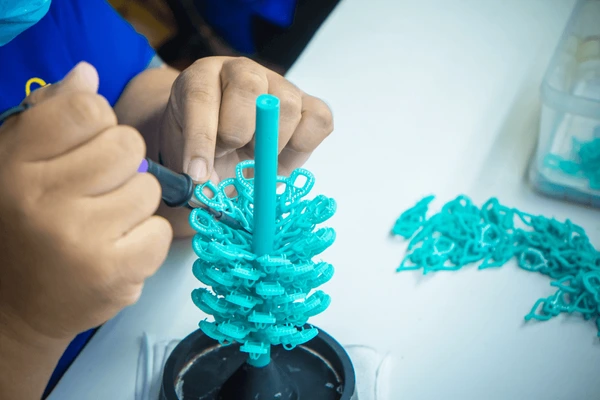

Lost Wax casting preparation - based on the design, the wax pieces are soldered onto a wax tree.

The wax models attached to a wax stem by hands. These form the channels through which the molten Gold or silver will flow into the mold.

Investment powder - The wax models that attached to the stem are placed into a special frame called a flask, which is then filled with an investment material that is allowed to harden.

After the investment material has set and hardened, the flask is placed in a special kiln to burn away the wax inside of it. When all of the wax is melted and burned away, the cavity, which is the mold, is left.

Melting - The gold is melted and depending on the alloy or type of the Gold (10k/14k/18k) or 925 silver used, temperatures can range from 1,617 degrees Fahrenheit and 2,006 degrees Fahrenheit. Gold can be combined with other metals like silver, copper and palladium to create different alloys of varying color (10k/14k/18k) and hardness.

Evicting - as soon as the metal cools, it needs to be removed from the investment material. This can be done through physical or chemical means. Each casting is cleaned and polished, and the sprues are cut off for recycling.

There are three main types of gold that typically are used in jewelry manufacturing:

White Gold — This is yellow gold that is generally mixed with silver and paladium then plated with white rhodium. The silvery white metal that gives white gold its shine and luster. The plating process involves dipping the jewelry into a solution containing rhodium, then running an electric current through it to bond the rhodium particles to the surface. This plating process needs to be redone periodically because the rhodium will wear off over time.

Yellow Gold — Yellow gold is typically alloyed with copper, silver or zinc, with the gold taking on a more reddish or greenish hue depending on the metal of which it is mixed.

Rose Gold — The pinkish color of rose gold is the result of yellow gold being alloyed with different levels of copper and silver.

The following chart explains how much gold is present in the different karats:

24K = 99.9 percent gold

22K = 91.6 percent gold

18K = 75 percent gold

14K = 58.3 percent gold

10K = 41.7 percent gold

Silver Jewelry Casting

N.E.F is extremely experienced at casting 925 silver. We know which techniques to use and have access to the latest specialized 925 silver casting equipment. The combination of experience and access to specialized equipment means that we can turn your designs into physical jewelry.

Our clients choose to work with our silver casting experts for the following reasons:

• We use only 100% Recycled silver (Certified)

• Creation of high-resolution reproductions when we use high-quality silicone molds.

• Use of cutting-edge molding and photopolymer technologies.

• All silver jewelry casting goes through a multi-step quality assurance process that includes expert casting preparation, final magnetic tumbling, and individual laser review

Ready to commence or further assistance is needed?

Leave us a message and we guarantee to provide you with a prompt response within the same day.